As you may have noticed, I started my CNC machine build with the idea of machining soft metals. However, machining metals and high spindle speed do not mix very well. When you use some small endmills you really do not need anything lower than 8000 (especially with carbide bits). But what if you need to surface a stock with a 1" fly-cutter? There is no way you can do that at 8000 RPM.

The problem, however, is that most consumer routers are designed for woodwork. So they are naturally fast. For example, the router I am using is Kress FME-1050. And its RPM range is 8000 - 32000. Awesome for fine engraving, but a disaster for surfacing.

Still hoping that there will be a miracle I connected my spindle to the Variac to see how it reacts to the lower voltage. Well, I honestly have no idea what those Germans at Kress have put into the circuit, but the RPM have not dropped until I reduced the voltage to 80V. And the torque naturally became very poor. What I decided to do is to open up my spindle and somehow tweak or replace the speed control circuit so that it allowed me to go lower than 8000 RPM - to 2000 RPM or even 1000 RPM.

When I opened the unit, it was obvious there was no way to modify the circuit - all components were covered with epoxy, so the only option left was to use a third-party motor controller. After some searching and reading, I decided to buy a KBIC controller made by KB Electronics. They have a wide range of models to choose from, and my choice was KBIC-240D. I have ordered a fuse kit as well.

While waiting for the package to arrive, I examined the Kress motor. It turned out, that the armature was split in two halves, and the field is connected in series between them. The easiest solution was to use the serial connection; however, I might decide to try a shunt configuration later.

Click on the pictures to enlarge.

|

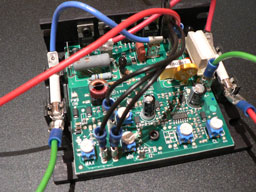

This is a close shot of the KBIC motor driver. It has very convenient connectors and is quite easy to hook up. |

|

|

I have made up temporary connections to check if the whole thing will work. I switched on the power and the motor started to run. Everything worked as it should: the potentiometer controlled the speed of the spindle. I noticed, that the torque still drops at low RPM, but the drop was not as bad as with Variac. |

|

|

This is the picture of the "Kress surgery" - the spindle is stripped of the speed control circuit and hooked up to the KBIC controller. |

|

I had made a quick test with a 1" Grizzly fly-cutter and was able to make a very light cut in the chipboard (0.004" depth of cut, 10 ipm, approximately 2000 RPM).

This is work in progress. I am still waiting for the tachometer to measure RPM precisely. And I still need to check the spindle with aluminum stock. Please check this page for updates.